Step#1 Gather Ingredients

Gathering the ingredients is the initial step in producing sunscreen. These may include active ingredients that absorb or reflect UV rays. These ingredients help to stabilize the sunscreen and improve its texture and application.

Step#2 Mix Ingredients

Once you’ve got all your ingredients together, it’s time to mix! Start by combining the active ingredients in a bowl and stirring until they form a thick paste.

Step#3 Filter the Mixture

We filter the mixture to get rid of any dirt and bits that may have been stirred up while mixing. This ensures a totally clean and pure end product.

Step#4 Sterilize the Mixture

The mixture is usually sterilized to make sure that any germs are eliminated. Heat or chemical sterilants are usually used for this purpose.

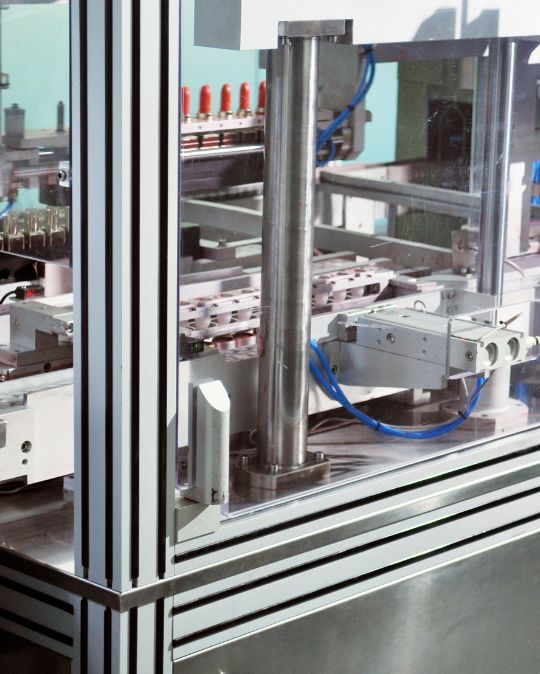

Step#5 Filling and Packaging

Once the sunscreen has reached the desired consistency. It is now ready to be filled into bottles or tubes and packaged.

Step#6 Quality Control

Test sunscreen before shipping to ensure quality. This may include tests for stability, effectiveness, and safety. At Nako Cosmetic, they ensure all products meet high standards via rigorous testing.

Step#7 Shipping

After passing quality control, sunscreen is shipped to retailers for purchase.