Step #1: Formulation and ingredient preparation

The first step in the mascara manufacturing process is to create the formula. This typically includes a combination of waxes, pigments, and emulsifiers. The ingredients are measured and combined in the appropriate proportions.

Step #2: Melting and Mixing

The ingredients are then heated and melted to create a homogenous mixture. I suggest using a heating device like a double boiler.

Step 3: Cooling and Homogenizing

After the mixture is heated and melted, it is cooled down to a workable temperature. This is done by placing the mixture in a cold water bath. Homogenization emulsifies ingredients, creating smooth, stable product.

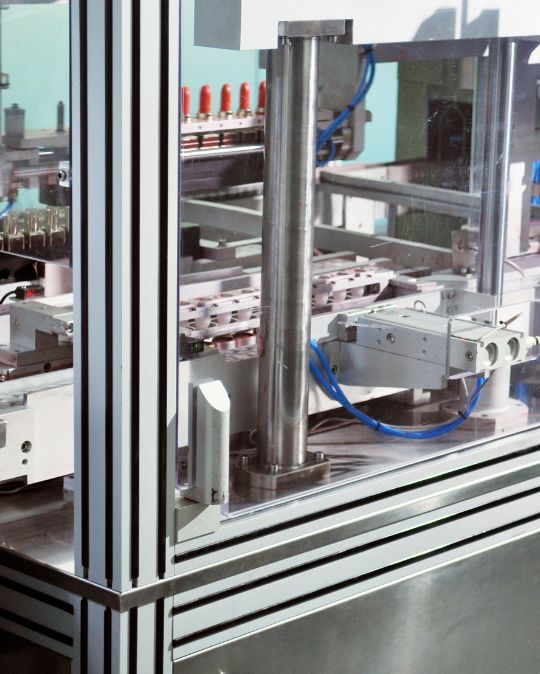

Step #4: Filling and Packing

Once the mascara is cooled and homogenized, it is ready to be filled into tubes. This step can be done by using a filling machine or by hand. The mascara tubes are then capped and labeled.

Step#5 : Quality Control

Before the mascara is shipped, it is inspected for any defects or quality issues. This includes checking the consistency, color, and fragrance of the mascara. Any mascara that does not meet the quality standards is rejected and not shipped.

Step #6: Shipping and Distribution

After quality control passed, package and ship to distribution centers or retailers. At Nako Cosmetic, we ensure that the mascara is efficiently distributed to customers.