Step#1 Ingredient Preparation

First, the manufacturer will source and prepare the ingredients needed. Such as pigments, binders, fillers, and other ingredients. Which are specific to the type of highlighter being made.

Step#2 Formulation

The next step is the formulation process. This is where cosmetic scientists create the specific formula for each product. This process involves mixing and blending the ingredients together. This is to create the desired color, texture, and finish.

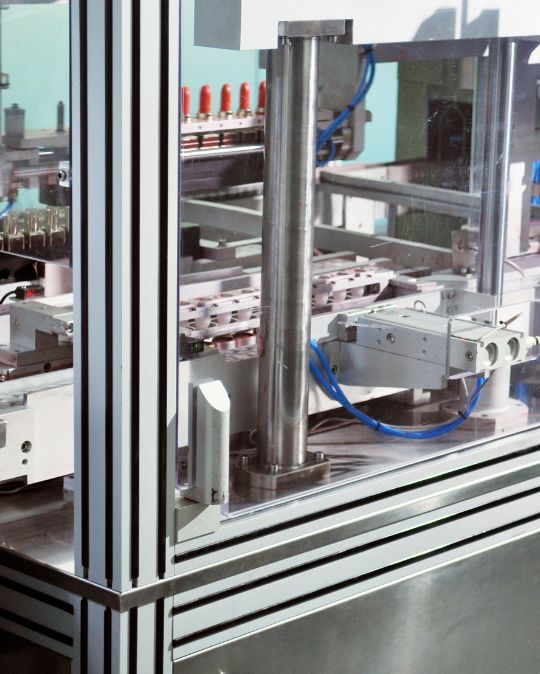

Step#3 Production

Once the formula is developed, the product is then produced in large quantities. This typically involves using manufacturing equipment such as mixers, rollers, and packaging machines. At Nako Cosmetic, we use state-of-the-art manufacturing equipment. To ensure that our products are of the highest quality.

Step#4 Quality Control and Inspection

Throughout the manufacturing process, the manufacturer will conduct quality control checks and inspections. To ensure that the product meets the desired specifications and standards. The Private Label Highlighter manufacturer will also test for microbiological activity. They also check stability and compatibility. To ensure safety for the customer.

Step#5 Packaging and Labeling

After the product is made, it will then be packaged and labeled. Providing customers with all the necessary information about the product. I suggest to ensure that the packaging and labeling are consistent with the brand image. and that they include all relevant information