Nako Cosmetic manufacturing process for hand wash typically involves the following steps:

Step#1 Raw Material Preparation

The ingredients required for hand soap include a mixture of oils, alkali, and water. These are usually measured and blended together to create the perfect product.

Step#2 Mixing

The ingredients are mixed together in a large mixing tank. The mixture is heated and agitated to ensure that all the ingredients are fully combined.

Step#3 Homogenizing

The mixture is then run through a homogenizer which breaks down any large particles. This ensures that the product is smooth and uniform.

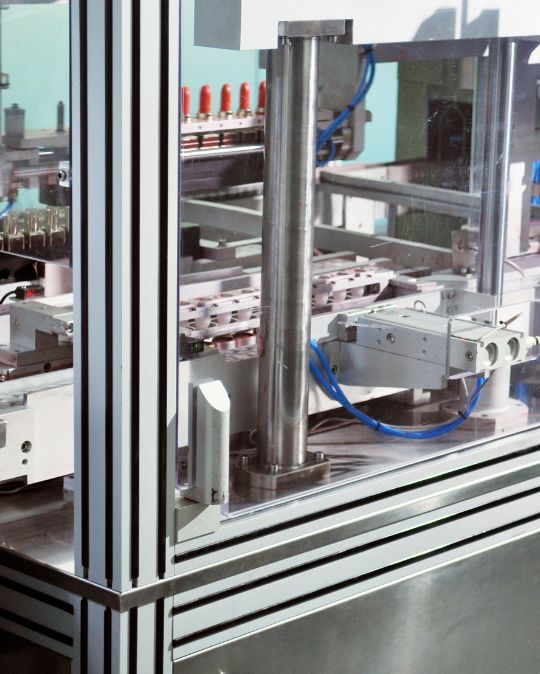

Step#4 Filling and Packaging

The hand wash is then poured into bottles or dispensers, and the bottles are sealed. This step is usually done in an automated process.

Step#5 Quality Control

Quality control measures are taken to guarantee the product is safe and effective. This includes lab testing for pH, consistency, and microbial contamination.

Step#6 Shipping

After passing quality control. They send out the product to warehouses or retailers for distribution.